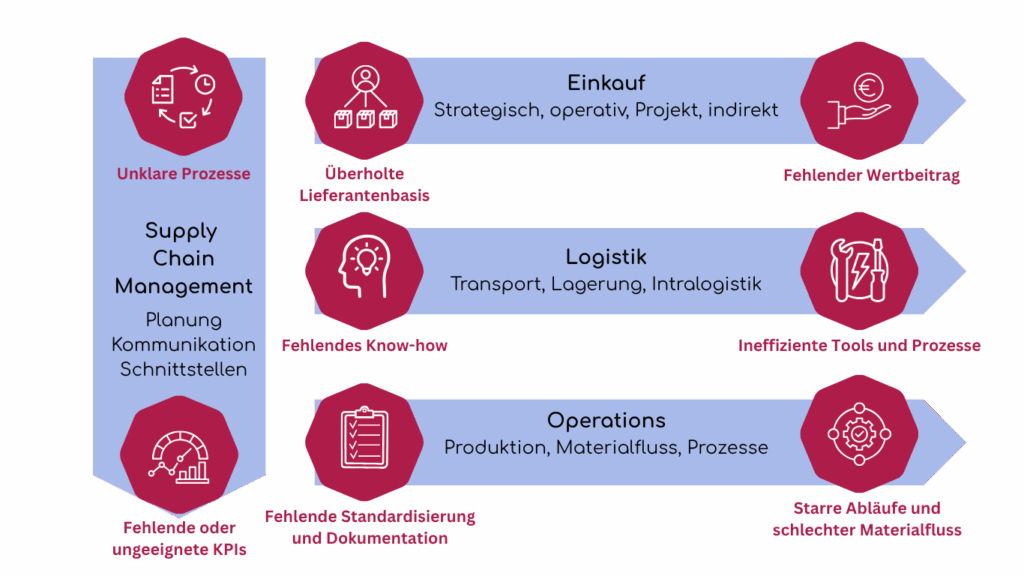

Procurement · Logistics · Operations

Let's fix your Supply Chain

Ich unterstütze mittelständische Unternehmen und wachstumsstarke Startups dabei, ihre Supply Chain zu stärken. Fundiert, pragmatisch und mit 20 Jahren Erfahrung.

From analysis and solution design to implementation:

I work with you to build a supply chain that performs in practice, is embraced by your team, and delivers real results.

Not just less chaos.

But greater clarity, better efficiency, and a real competitive edge.

Most supply chains work. But they don’t run smoothly.

In manufacturing, the factory is the heart of the business.

But a strong heart can only keep beating when everything around it is working in sync. Procurement, logistics, operations – they all need to support the flow.

Too often, that flow gets disrupted. Work gets done, but not without friction.

Over time, small issues start to build up:

KPis that miss the point.

Tools that don't connect.

Processes no one has touched in years.

It’s not a crisis. But it’s enough to slow everything down. Decisions take longer. Mistakes happen more often. People start to feel the drag.

I’ve seen it many times. And that’s exactly where we start.

From Analysis to Action - what to expect when we work together

My approach is structured and hands-on, built on a simple principle: understand, decide, act.

Below, you'll find an overview of how I work - and some starting points for tackling common challenges.

My Approach

Soild analysisListen. Understand.

Make key issues visible.

Support through implementationI don't stop at the PowerPoint stage.

I stay involved until real impact is visible.

Step by step - with Kaizen and PDCANo big-bang perfection. Instead: small steps, fast feedback, lasting standards.

Grounded in Kaizen and the PDCA cycle. Practical, effective, and scalable.

My experience is broad. That's what enables real implementation.

Clear structure, solid decisions, practical implementation.

Let’s talk about where to start in your business.

Three smart reasons to bring in outside help

Sure, that can work. But often, it’s the longer, more expensive path.

When time is short, resources are stretched, and experience matters, an external expert simply makes more sense.

The right expertise, right when you need it

You don’t need to build a new team for a well-defined challenge.

I deliver targeted know-how and hands-on support – and leave you with a setup that runs smoothly even after the project ends.

You stay lean and gain capability.

Predictable costs, no long-term overhead

Hiring takes time. It ties up budget and adds fixed costs that stick around.

An external consultant gives you exactly what you need – no overhead, no long-term burden.

Perfect for tight timelines and clearly scoped projects.

Fast. Focused. Scalable.

No hiring delay. No ramp-up. No red tape.

As an independent consultant, I can step in and get moving right away.

And if the scope expands, I can bring in additional resources through my established network.

I work best with mid-sized companies, scale-ups building industrial operations, and corporate teams looking for sharp, independent support.

I speak your language – and I know what your day-to-day really looks like.

Your success is my product.

What former leaders say about working with me

In previous roles, I led projects that made a real difference – and received feedback I’m still proud of today.

Here are a few excerpts from reference letters and internal reviews I’ve collected over the years.

Until then, I’d be happy to speak with you personally – and explore how I can support your business.

How I work with clients – flexible, focused, effective

No two companies are the same.

And no two projects should follow the same script.

That’s why I tailor my role and level of support to fit your situation – whether it’s a quick intervention or a longer-term transformation.

Von der punktuellen Intervention bis zum mehrmonatigen Transformationsprojekt.

Supply chain challenges come in all shapes and sizes – and the right approach depends on your goals, your team, and your timeline.

Sometimes it’s an hour of focused sparring. Sometimes it’s a full reset of how things run.

Whatever the scope, my approach stays the same: clear analysis, practical solutions, and real follow-through.

Let’s figure out what makes sense for you.

Project formats

Change InitiativeI lead clearly defined improvement or transformation projects – as project manager and change driver.

Strategic ConsultingWe take a close look at what’s holding your operations back, identify where the leverage points are, and turn ideas into a concrete plan. Then we drive implementation together – until the change shows up in results.

Interim ManagementI step in short-term to cover a leadership gap – keeping things steady or helping build something new.

Sparring, Workshops, CoachingFocused input in compact formats – for founders, execs, or leadership teams. Built to cut through complexity and deliver real-world impact.

About me

Throughout my career, I’ve worked in a wide range of organizations – from global corporations with hundreds of thousands of employees to small, founder-led businesses.

What they all had in common: my work always focused on the supply chain – procurement, logistics, material flow, and process improvement.

I’m a trained industrial engineer who enjoys working at the intersection of numbers, systems, and real-world operations. Math was always my strongest subject, and I’ve kept that mindset – approaching problems analytically and aiming to bring clarity to complexity.

I’ve held leadership roles for over 14 years and worked across several industries in different capacities. What drives me today is helping others succeed – by sharing experience, creating practical solutions, and supporting teams and businesses in their development.

Alongside German, I speak English and Spanish at near-native level and have a good working understanding of French and Italian. International collaboration and cross-cultural experience have been key parts of my career – and continue to shape how I work.

I’m based in Frankfurt. Outside of work and family, I enjoy sports and endurance training.

I’ve completed an Ironman and several shorter races – these days, I train mainly to stay healthy and focused.

What if the solution was already within reach?

Sometimes a fresh perspective is all it takes to unlock progress.

Frequently Asked Questions (FAQ)

In this section, you'll find answers to common questions about how I work, the services I offer, and what to expect when we collaborate.

Didn’t find what you were looking for? Feel free to send me a message — or book a free initial consultation to discuss your questions in person.